Are you looking for high-quality tamsulosin intermediates to boost your pharmaceutical manufacturing process?

Our premium-grade intermediates are meticulously designed to meet the most stringent industry standards, ensuring optimal performance and efficiency.

With our reliable supply chain and expert team, you can trust us to deliver top-notch tamsulosin intermediates that will elevate your production to new heights.

Contact us today to learn more about our superior tamsulosin intermediates and take your pharmaceutical manufacturing to the next level!

Tamsulosin Intermediates: Overview

Tamsulosin intermediates are key components in the synthesis of the active pharmaceutical ingredient Tamsulosin, which is used to treat symptoms of benign prostatic hyperplasia (BPH). These intermediates play a crucial role in the production of Tamsulosin by undergoing various chemical reactions to form the final product.

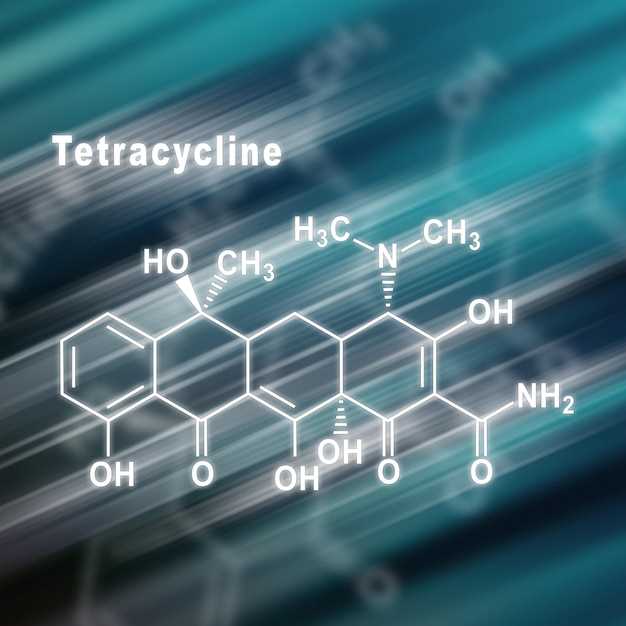

The chemical structure of Tamsulosin intermediates is carefully designed to ensure the successful conversion into the desired compound. These intermediates possess specific functional groups and bonding patterns that allow them to react efficiently in the synthesis process.

The purity and quality of Tamsulosin intermediates are essential for the overall effectiveness and safety of the final product. Strict quality control measures are implemented during the production of these intermediates to ensure consistency and reliability in the pharmaceutical industry.

Overall, Tamsulosin intermediates play a critical role in the pharmaceutical manufacturing process, contributing to the development of high-quality and effective medications for patients suffering from BPH.

Chemical Properties and Structure

Tamsulosin intermediates are crucial components in the pharmaceutical industry due to their unique chemical properties and structure. These intermediates play a vital role in the synthesis of tamsulosin, a widely used drug for the treatment of benign prostatic hyperplasia (BPH).

The chemical structure of tamsulosin intermediates consists of specific functional groups and bonds that are essential for the pharmaceutical activity of the final product. These intermediates undergo various chemical reactions and transformations during the synthesis process to ensure the purity and efficacy of the drug.

By understanding the chemical properties and structure of tamsulosin intermediates, pharmaceutical companies can optimize their synthesis methods, enhance the quality of the final product, and meet the growing demand for tamsulosin in the market.

Uses in Pharmaceutical Industry

Tamsulosin intermediates play a crucial role in the pharmaceutical industry due to their versatile applications. These intermediates are key components in the synthesis of tamsulosin hydrochloride, a medication commonly used to treat symptoms of benign prostatic hyperplasia (BPH) in adult males.

Due to their high purity and quality, tamsulosin intermediates are essential for ensuring the efficacy and safety of the final pharmaceutical product. They serve as building blocks in the manufacturing process of tamsulosin hydrochloride, facilitating the conversion of raw materials into the active pharmaceutical ingredient.

Moreover, tamsulosin intermediates undergo stringent quality control measures to meet regulatory standards and ensure consistency in the production of tamsulosin hydrochloride. The pharmaceutical industry relies on these intermediates for the reliable and efficient synthesis of tamsulosin, enabling the production of high-quality medications for patients in need.

Synthesis and Production Methods

When it comes to the synthesis and production of Tamsulosin intermediates, it is essential to follow stringent protocols to ensure the highest quality and purity of the final product. The synthesis process typically involves several key steps, including the selection of raw materials, reaction optimization, purification techniques, and quality control measures.

Raw Materials: The synthesis of Tamsulosin intermediates begins with the selection of high-quality raw materials that meet the stringent standards set by regulatory authorities. These raw materials form the foundation of the entire synthesis process and play a crucial role in determining the quality of the final product.

Reaction Optimization: The next step in the synthesis process involves optimizing the reaction conditions to ensure maximum yield and purity. This often involves fine-tuning various parameters such as temperature, pressure, and reaction time to achieve the desired outcome. State-of-the-art equipment and precise control systems are typically employed to facilitate this optimization process.

Purification Techniques: After the reaction is complete, the crude product undergoes purification techniques to remove impurities and unwanted by-products. Various methods such as recrystallization, filtration, and chromatography are commonly used to ensure the final product meets the required purity standards.

Quality Control Measures: Throughout the synthesis and production process, rigorous quality control measures are implemented to monitor the quality and consistency of the Tamsulosin intermediates. Advanced analytical techniques such as HPLC, GC-MS, and NMR spectroscopy are used to verify the identity, purity, and composition of the final product.

Overall, the synthesis and production of Tamsulosin intermediates require a delicate balance of precision, expertise, and state-of-the-art technology to ensure the highest quality standards are met. By following strict protocols and employing advanced manufacturing practices, manufacturers can produce Tamsulosin intermediates that meet the demanding requirements of the pharmaceutical industry.

Quality Control and Testing Procedures

Quality control and testing procedures are crucial in ensuring the consistency and purity of tamsulosin intermediates. Here are some key steps involved in the quality control process:

- Physical Appearance and Color: The intermediates are visually inspected for any abnormalities in appearance and color.

- Chemical Composition: Various analytical techniques such as HPLC and GC are used to analyze the chemical composition of the intermediates.

- Purity Testing: The purity of the intermediates is determined using methods like titration and spectroscopy.

- Impurity Analysis: Impurities are identified and quantified to ensure they are within acceptable limits.

- Microbiological Testing: Microbiological testing is performed to check for any microbial contamination.

- Stability Testing: The stability of the intermediates is evaluated under different conditions to ensure their shelf-life.

By following stringent quality control and testing procedures, manufacturers can guarantee the high quality and safety of tamsulosin intermediates, meeting the regulatory requirements and market demands with confidence.

Market Demand and Growth Prospects

The market demand for tamsulosin intermediates is on the rise due to the increasing demand for the final product in the pharmaceutical industry. Tamsulosin is widely used in the treatment of benign prostatic hyperplasia (BPH) and helps in relieving the symptoms associated with it.

With the aging population and the rising prevalence of BPH, the market demand for tamsulosin intermediates is expected to grow steadily in the coming years. The pharmaceutical industry is constantly looking for high-quality intermediates to ensure the efficacy and safety of the final product.

Key Growth Drivers

- Increasing prevalence of BPH

- Rising geriatric population

- Advancements in drug development

- Growing healthcare infrastructure

The growth prospects for tamsulosin intermediates look promising, with pharmaceutical companies focusing on developing innovative treatment options for urological disorders. As a key player in the supply chain, the demand for tamsulosin intermediates is expected to remain strong in the foreseeable future.